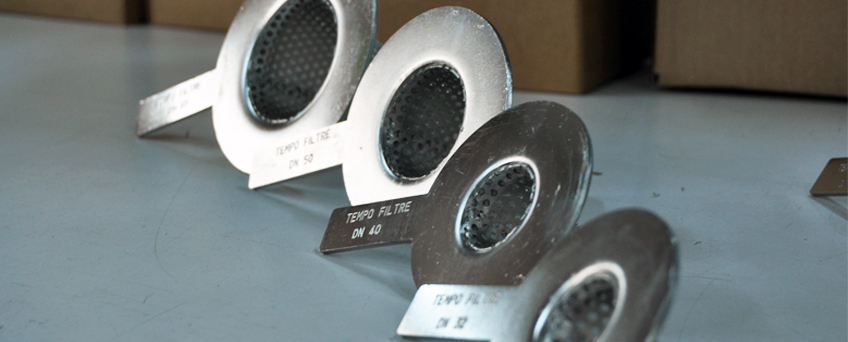

Chromium Filters

Chromium Filters

These are stainless steel woven wire filters and have a more excellent construction, for their pore distribution, compared to synthetic and fibre filter media. They have nominal filtration capability thanks to the distinct mesh structure (304 and 316 Cr-Ni). Moreover, they have mesh-based versions offering a more resistant construction, such as Plain Dutch weaves (high flow,low pressure), Twilled Dutch weaves (nominal flow, precise filtration), and Reverse Dutch Weaves (low flow, precise filtration, high pressure).

On the other hand, the new-generation felt media have relatively lower filtration (5µ-10µ) capability.

Chrome filters are rather used as suction filters in the tanks of hydraulic systems, and also employed for fuel filtration with PTFE coating.

What are the Points to Consider in Chrome Filters?

Since chrome filters are widely used, it is one of the difficult filter types to manufacture. Many issues need to be considered during its production. When it is tried to be produced amateurly, many problems occur in the place used. Therefore, it must be produced with expert workmanship.

The quality of the various chrome filters produced is determined by the use of appropriate materials in filter production and the fact that they are produced in real microns. The filters, which are produced by experts who know their job, will both last longer and keep your machinery and equipment away from unexpected dangers. The produced filter should be designed to withstand high pressures. Experience is one of the most important factors in filter production. As Tempo Filter, we offer our long years of experience and knowledge to our customers.