Hydraulic Filters

Hydraulic Filters

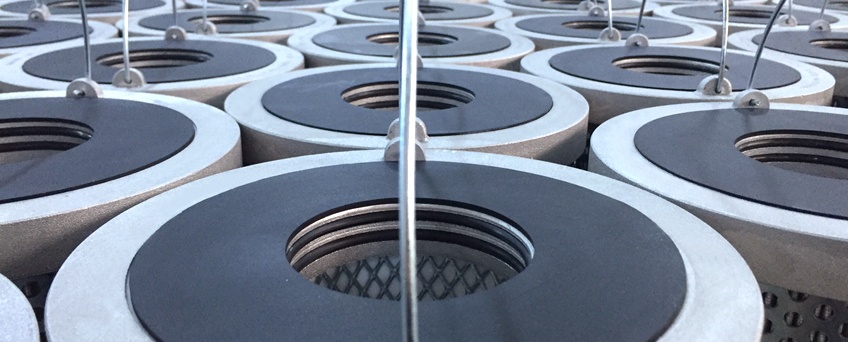

Hydraulic filters are classified in three major groups: pressure filters, return filters and suction filters. These filters are designed to keep the fluid clean in order to protect hydraulic members from abrasion, and avoid mechanical failures.

Pressure line filters can be discussed in two categories: High pressure (420bar) and low pressure (21bar) system filters. These filters have superior filtering capability as precise as 3µ, 6µ,10µ, 20µ and 25µ. Such a precise filtration capability owes to a fibreglass- (microglass) based laminated medium in the filter’s construction. This system yields a filtration precision in the order of 25µ, on the other hand chrome (mesh) filters are employed in the suction line.

Scientific studies on hydraulic systems reveal that 70% of the incidents are due to abrasion (50% mechanical abrasion and 20% corrosion) followed by accidents (15%) and expired lifetime (15%). Thanks to the ultra-high dust holding capacity of the media as a part of the system’s high quality standard, performance and service life of the major system components, i.e cylinders, servo valves, hydraulic motors as well as other auxiliary equipment and members are improved and zero downtime is guaranteed in the hydraulic system.

The company uses high-quality Fibreglass (microglass) as the key filtration media in its diversified filter range for high-, medium- and low-pressure systems and procures it from two global giants, H&V and Lydall. On the other hand, the company has the capability to manufacture in its own Turkish plant equivalent same-quality versions of hydraulic filters procured from different overseas providers.

https://tempofiltre.com/dust-collector-filter-bags-manufacturers/